We design & manufacture Fiber-Based Packaging Machinery

For over three generations, we’ve specialized in designing high-quality machinery, including Carton Flexo Printing machines, Corrugated Board production lines, Pulp & Paper machines, and Egg Tray machinery. With a global team of expert designers and state-of-the-art manufacturing facilities, we combine advanced technology and decades of experience to deliver innovative, reliable, and durable solutions.

Three Generations of Innovation

Family Values

Guided by principles passed down through three generations, we value quality, reliability, and customer satisfaction

Legacy of Innovation

Since our founding, we have been at the forefront of paper and packaging machinery design

Commitment to the Future

We are dedicated to sustainable practices and innovative solutions for the packaging industry

Flexo Printing & Carton Machine

High-Precision Printing

Efficient Converting

Automated Solutions

Maximize productivity with our automated carton handling systems.

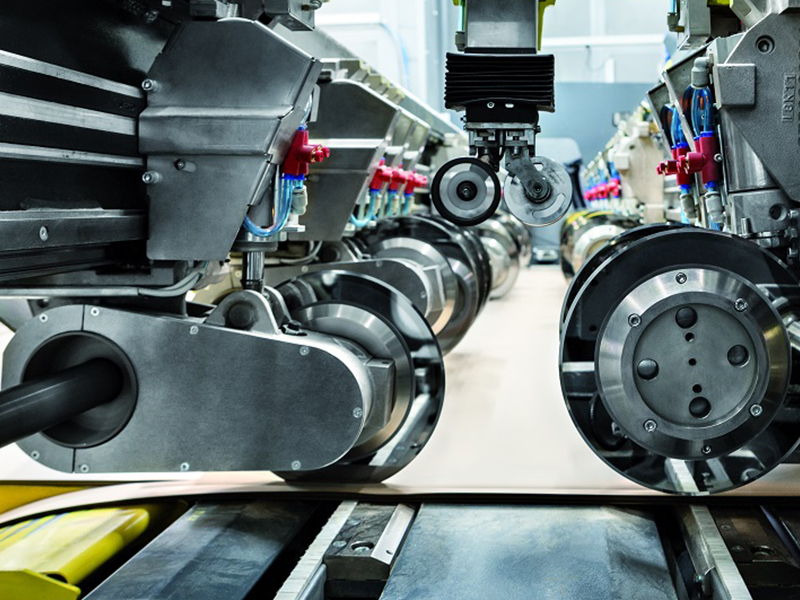

Corrugated Board Production Lines

Paper Feeding

Pre-made paper rolls (liners and fluting) are fed into the corrugated board production line. These rolls are sourced from paper mills and are ready for processing

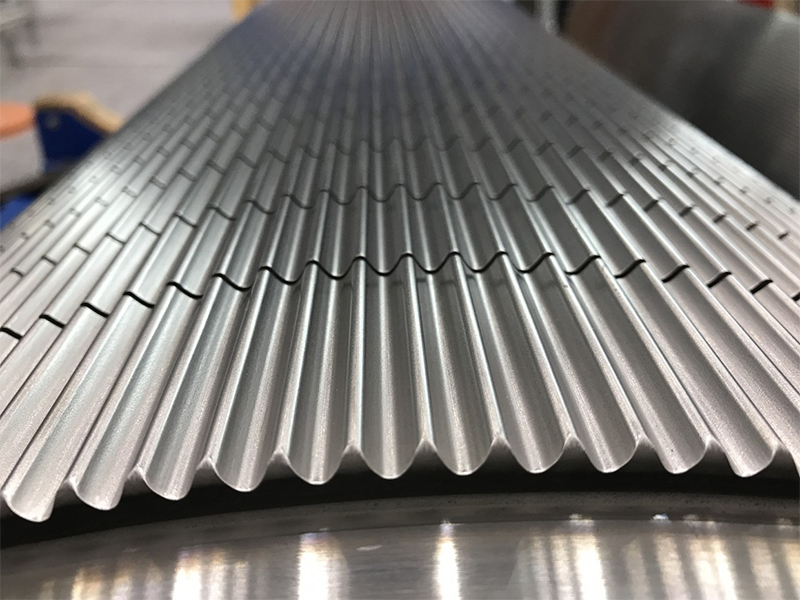

Corrugating

The fluting paper passes through corrugating rollers to create the wavy, fluted structure. This step gives the board its strength and rigidity

Double Facer

In the glue machine, a fluted medium is bonded between two flat linerboards using adhesive, resulting in a single-faced corrugated sheet (2-ply). This sheet can then be combined with additional liners to produce double-faced (3-ply), 5-ply, or 7-ply corrugated boards

Cutting & Stacking

The corrugated board is cut into specific sizes and shapes as required using Slitter and Cutt-off. The finished boards are then stacked and prepared for shipping or further processing, such as printing or die-cutting

Paper Machine

Introduction to Our Paper Machine

Discover our advanced paper machine, engineered to deliver unparalleled efficiency and precision in paper production. Designed for both large-scale industrial operations and specialized manufacturing, our machinery ensures high-quality output while prioritizing sustainability and innovation.

Key Features and Technology

Our paper machine integrates cutting-edge technology to streamline the entire papermaking process. From pulping and refining to sheet formation and drying, every stage is optimized for maximum productivity and minimal waste. Equipped with automated controls, real-time monitoring, and energy-efficient systems, our machine guarantees consistent performance, superior paper quality, and reduced operational costs.

Sustainability and Versatility

Committed to environmental stewardship, our paper machine supports the use of recycled materials, helping you transform waste paper into valuable products. It is versatile enough to produce a wide range of paper types, including packaging paper, kraft paper, and specialty papers, catering to diverse industry needs. By choosing our paper machine, you not only enhance your production capabilities but also contribute to a greener, more sustainable future.

Egg Tray & Fiber Packaging Machine

From Waste to Value: The Fiber Molding Process 🏭♻️

- Waste Paper – Collected and repurposed as raw material.

- Pulp Preparation – Waste paper is mixed with water and processed into a uniform pulp.

- Forming (Molding) – The pulp is shaped into egg trays using precision molds.

- Drying – Trays pass through a multi-layer dryer for efficient moisture removal.

- Stacking & Packaging – Finished egg trays are neatly stacked and packed for distribution.

A sustainable and eco-friendly solution for protective packaging! 🌱📦

A world-class group

Designing solutions for a Global Future